Robotics

Easy-to-program industrial robots in the lower to medium price range help to simplify repetitive work steps and utilise skilled workers for more meaningful work activities. After a free feasibility study, we will give you an overview of the possibilities of using industrial robots to your advantage.

Phone: +49 (0)511/955 733 46 | smartfactory@schreiber-weinert.de

Paging Systems

Being able to contact employees or suppliers promptly helps to simplify the organisation and avoid time and friction losses. At the loading bay, SW paging systems help to control delivery traffic just in time.

Phone: +49 (0)511/955 733 46 | smartfactory@schreiber-weinert.de

Augmented Support

A serviced or defective machine is at a different location? The SW head-mounted displays (displays that can be worn like glasses) provide you with tutorials or live instructions directly during maintenance and repair. No need to flip through manuals.

Phone: +49 (0)511/955 733 46 | smartfactory@schreiber-weinert.de

Preventive Maintenance

The monitoring of machines and rooms for noise, vibrations, temperature and humidity is required in many places in companies – and not just on machines, but also in offices, workshops and warehouses. The key to efficiently analysing the collected information is the right software – which we offer as a cost-effective cloud solution and can use to provide early warnings of defined exceptional conditions at any time.

Phone: +49 (0)511/955 733 46 | smartfactory@schreiber-weinert.de

What would you like to improve in your company?

Productivity, quality, lead time, preventive deviation alerts?

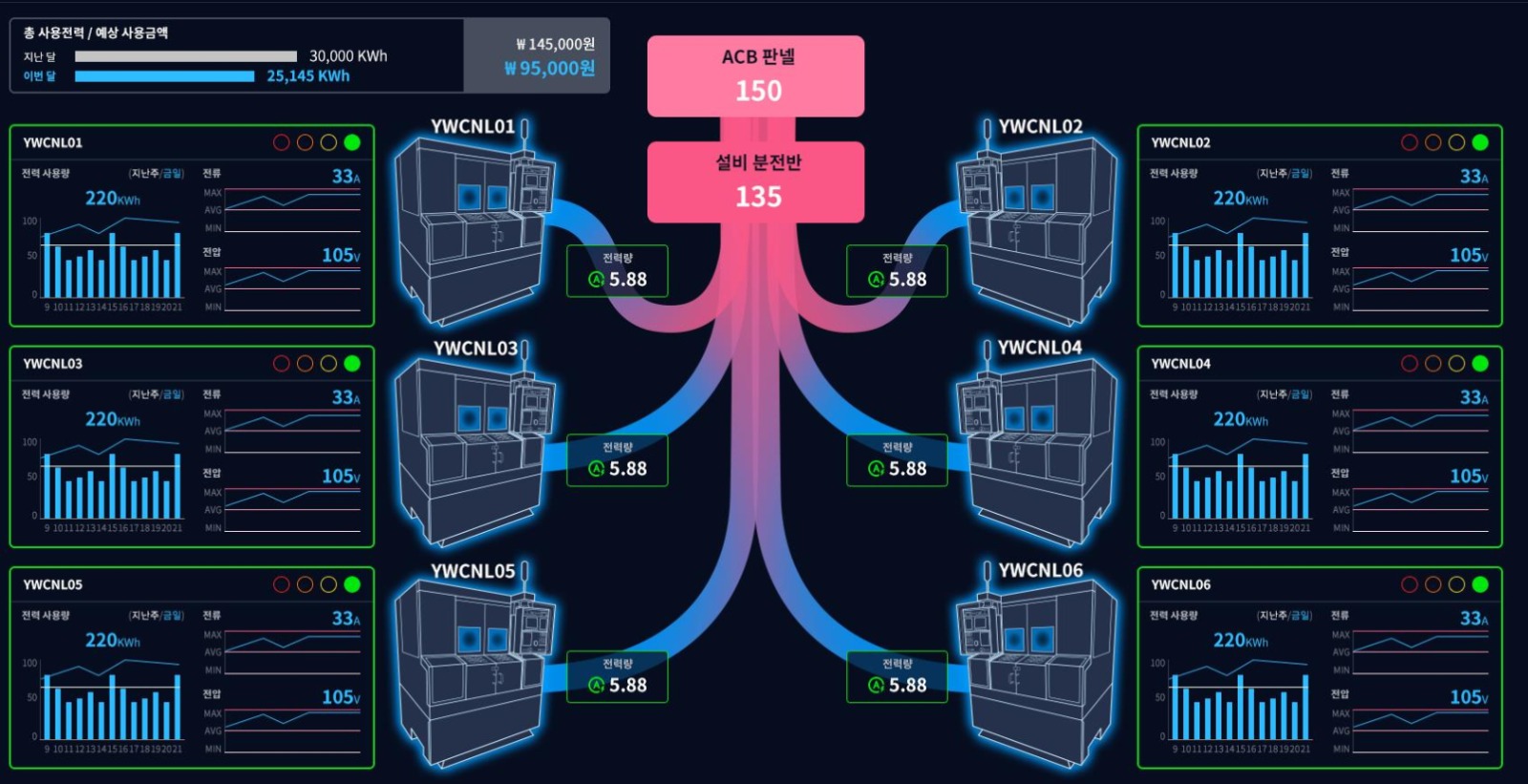

With WimFactory – one of the best Smart Factory Total Management solutions – you will achieve your goals. WimFactory collects, analyzes, and visualizes data, enabling users to optimize manufacturing processes and proactively resolve issues.

WimFactory consists of the IIoT device Wicon and the Wim-X Smart Factory Management Solution software. By simply connecting to commercial sensors or PLCs, Wicon automatically gathers real-time data and transmits it to the cloud. The Wim-X software then analyzes and visualizes this data. Using these insights, Wim-X provides efficient operational data analysis as well as preventive maintenance.

- Staff can step in and take corrective action as soon as the measurement data indicate that the defined acceptable range is about to be exceeded.

Real-time monitoring:

With the customizable dashboard, employees can see the factory’s status at a glance.

Analysis reports:

Employees are freed from repetitive documentation tasks.

Advantages

- Easy installation: No significant changes to equipment or wiring are required—unlike with other providers. Data measurement devices transmit the data wirelessly to the cloud.

- Usable in any process: Monitoring of temperatures, sound levels, and vibrations.

- Deployable in any company or industry: Company size and industry do not matter.

- Short installation time: Installation consists of mounting the measurement devices and configuring the software.

- Cost-effective: WimFactory is cloud-based software. Cloud services are billed based on usage volume. There is no fee for the Wim-X (software) license.

- Highest data-processing speeds: WimFactory’s data engine processes large volumes of real-time data at high speed—300,000 data points per second.

- Accurate data analysis: The accuracy rate is 94%. The algorithm used for this has been patented in the USA.

Main functions:

- Preventive event alerting: Alarms can be configured so that, when measurements fall outside the specified range, a warning is sent to desktop or mobile devices.

- Real-time Monitoring: The fully customizable dashboard lets the controller view the status of a machine or room at a glance, at any time.

- Reports with analysis data free the operator from repetitive documentation tasks.

SCHREIBER + WEINERT is the official distributor of WimFactory / ulalaLAB® in Deutschland

Team Smart Factory

Phone: +49 (0)511/955 733 46

smartfactory@schreiber-weinert.de

Manufacturer’s website: http://www.wimfactory.com/de